Mon to Sat: 09:00 am to 05:00 pm

Mon to Sat: 09:00 am to 05:00 pm

Brands face many different considerations when taking a new product to market or revamping an older brand name. Costs, ease of manufacture, shelf-life, customer appeal and size amongst a myriad of other variables.

Yet, today, as pollution reaches critical levels, recyclability has to be one of the priority considerations. Legislation has been enacted through Extended Producer Responsibility (EPR) regulations that oblige ‘producers’ to adhere to recyclability guidelines. As importantly, environmental issues have become commonly understood by an increasingly better-informed public to the point where recyclability forms part of the purchase decision-making process.

Plastic packaging, which gets bad press, does achieve the hygiene, convenience and durability we might need. And PET (Polyethylene terephthalate) is actually 100% recyclable. The consideration then becomes, how do we make sure that the design of the product and packaging doesn’t lead to contamination of the recyclable product through the addition of extraneous elements?

It is also true that pollution is not only limited to visible litter but also includes microplastics from sources such as tyres and washing clothes. The latter is especially amplified due to so-called “fast fashion” - cheap clothes mass-produced to fit trending styles with a heavy reliance on non-biodegradable synthetic plastic fibres like nylon, polyester and spandex.

The environmental impact of a product and its packaging is largely decided at the design stage. Through thoughtful, interrogative design for circularity and recyclability, we can save resources, reduce waste, and ensure that products and their packaging have value in the recycling process.

Why Is the Roof So Important?

The roof is vital as it provides essential protection for your home. A compromised roof can lead to significant issues, particularly water damage. Water intrusion can cause mold growth, structural damage, and interior damage to ceilings and walls. Unaddressed, these problems can escalate, requiring costly repairs or even a complete roof replacement. Conducting a thorough roof inspection before purchasing a home can prevent these expensive and inconvenient surprises

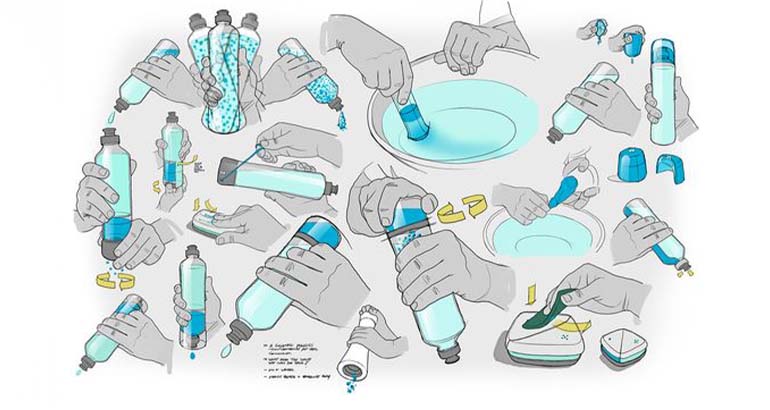

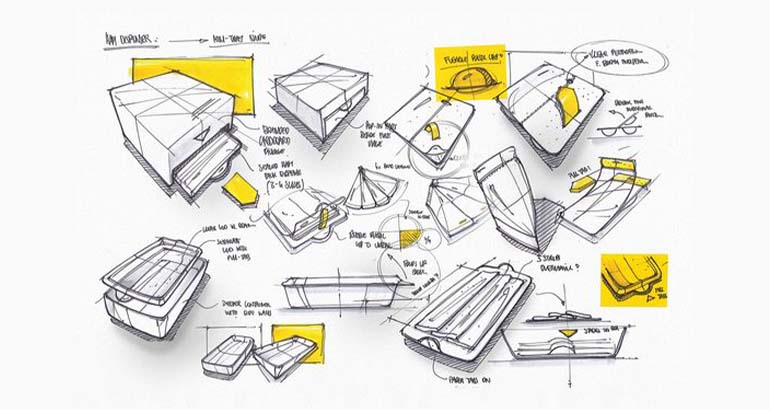

The idea is simple: first, design the product so that it can be 100% recyclable and is indeed recycled right here in Uganda. Design for circularity. Design so that a key objective is that the product or packaging that gets thrown away doesn’t end up in landfills causing pollution but back in the shops as a new product.

Guidelines for Designing for Recyclability

Reduce any gratuitous materials and packaging (that add no functional benefit) used in or on the product. Extra material or mixing of materials simply creates more waste, as it makes the product difficult to sort and recycle. Design packaging that is easy to disassemble and sort.

Localise material selection.

Use materials in your packaging that can be recycled in Uganda, where there is an end-use market. Speak to your Producer Responsibility Organisation, or ask your local recycling companies what materials they collect and recycle. Therefore, it’s important to design packaging that makes economic sense for local waste-pickers and recyclers, because if it has no end-use value, it will end up in landfill despite it being “recyclable”.

Fit for Purpose.

Consider a holistic approach to design that is suitable for the product and the packaging. Take into account the preservation and protection needs of the product. Be aware of unintended consequences that can solve one problem and create another one. Through careful selection, packaging can effectively serve its purpose while aligning with sustainability goals.

Assess environmental impact.

Evaluate the entire lifecycle of the product from how much energy it takes to make, to how easy it is to transport and distribute to any impact the use of the product may have. The level of recyclability will obviously have a key bearing on its environmental impact.

The global environmental crisis is reason enough for us to take decisive action now to reduce pollution. And we have the power to do it. By thinking smartly when we design and acting responsibly when using and disposing of products and packaging.

The global environmental crisis is reason enough for us to take decisive action now to reduce pollution. And we have the power to do it. By thinking smartly when we design and acting responsibly when using and disposing of products and packaging.

Leave a comment